Building an Obsolete Prototype AVR Replacement for a Honda EM500

I recently made a video on this Honda EM500 generator. A subscriber sent it to me after it started producing almost 200 volts out of the 120 volt outlet. The ultimate issue was that the automatic voltage regulator (AVR) had failed. The part was obsolete and not available new or used. Even worse Honda potted the board with a resin that could not easily be removed and did not publish any circuit diagrams. I did manage to find a new old stock AVR for $200 from a seller out of the Netherlands. I purchased what was the last one available for sale in the world.

A lot of these 40+ year old generators are new failing. Mechanically they are sound, but the electronics in the AVR are going bad. After publishing the first video a few came forward and offered to assist with designing a new replacement board. I sent the failed board to Bill. Within weeks he had produced several design options.

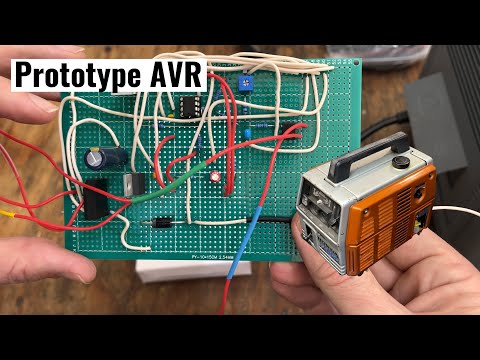

Today I am going to gather some more data, choose an AVR design and build a prototype board. I have zero board building experience. Should be interesting.

Generator Model: EM500

AVR Part: 32350-892-632

First Honda EM500 Video

Vintage Honda EM500 – High Voltage Problem

*** I no longer use Harbor Freight Super Heavy Duty Degreaser in my ultrasonic cleaner. Harbor Freight changed the recipe. The bottle previously stated “NON-CORROSIVE”. Now it says “CORROSIVE”, “do not user on Aluminum”. It now damages most carburetors. ***

Visit My Amazon Store:

https://www.amazon.com/shop/jamescondon

If you want to donate to the channel, you can use the YouTube “Super Thanks” feature or via PayPal: https://www.paypal.com/paypalme/jamescondonYT

#HondaGenerator #GeneratorRepair #SmallEngineRepair #SmallEngine #DIY #Fixed #Troubleshooting #howto

AVR, Alternator, Automatic Voltage Regulator, Depotting, EM500, Fixed, Generator, Hertz, High Voltage, Honda EM500, Honda, How To, How-To, Kill A Watt, Load Test, Obsolete, Oscilloscope, Prototype, Repair, Small Engine, Too Much Power, Troubleshooting, Vintage Honda

Hi generator fans, thanks for all the “Kudos”. I am the “Bill” James mentioned. After looking through the comments, I thought I would provide answers to the most asked questions plus, add some details to the tests done in the video to hopefully minimize confusion. First off “AVR” stands for Automatic Voltage Regulator, which is fully electronic, as opposed to electro-mechanical voltage regulators used on cars from the 1960’s and before. De-potting the original circuit was very difficult. I had to curve the potting away using a soldering iron and Honda’s board construction was very similar to pocket transistor radios manufactured in Asia in the 1960’s; parts were laid over parts squeeze the circuitry into a given space. The de-potting operation ended up being a destructive type, as removing the top layer of components, damaged both upper and lower layers. As each component was lifted from the board, a schematic was made of its attachment to the rest of the circuitry and, in many cases, the part marking was lost during the “dig” so, I had to calculate some of the lost values to make up a complete reverse engineering effort.

It’s good to see old equipment a second life 12:06

Sometimes it’s easier to design something from scratch rather than reverse engineer someone else’s mistake.

Another great video

Well, James, you lost me after the first five minutes, but that’s certainly not your fault! Up to now I’ve been able to gain bits and pieces of generator knowledge from you to the point that I almost understand most of the videos you’ve done. This one, on the other hand, shows me I have a lot more to learn in order to understand what’s going on under the (AVR) hood. As usual, a well produced video, so thanks a lot. ??

If you haven’t found someone already I’d be more than happy to design up a little PCB for ya.

It should be easy to design something that JLCPCB will assemble (so you just need to solder the wires on).

Masterclass

This is what the internet promised – right after listserv email connected groups of people who would help each other out – before forums… (and before a million other things)

This is the most informative generator channel I have seen. It taught me a lot of information regarding maintaining generators and small engine equipment. I also did some research for the hertz to rpm conversion. 1 rpm = somewhere around 0.016-0.017 hertz. Setting the generator speed at 3660 is at 61 hertz. To get 61.5 it’s generally a good idea to go for 3700 or slightly above because the engine speed will never be constant. It will always change a little. Also it depends on the load and what your doing with the generator. If I was going to place a heavy load on the generator, I would set the engine speed a little faster(around 62-63 hertz) so the engine will not drop below 58 hertz or 3500 rpm. And slightly increase the sensitivity of the governor a bit to help out. Also it’s imperative to change the oil frequently and shut your fuel valve off after your done and let it run until it quits. Or you can drain the bowl on the carb. Also letting a piece of equipment sit without being run will destroy it(if it’s gas powered). At least take it out once a month or 2-3 months and let it run for 20 mins. I take my generator out once a month and let it run for 20 mins and never had an issue. Proper equipment maintenance is key.

You are switching an inductive load which causes the counter EMF. Use a snubber circuit to kill it